Ø tubo

Piping Ø

20

32

50

75

110

160

250

355

450

90,0

560

105,0

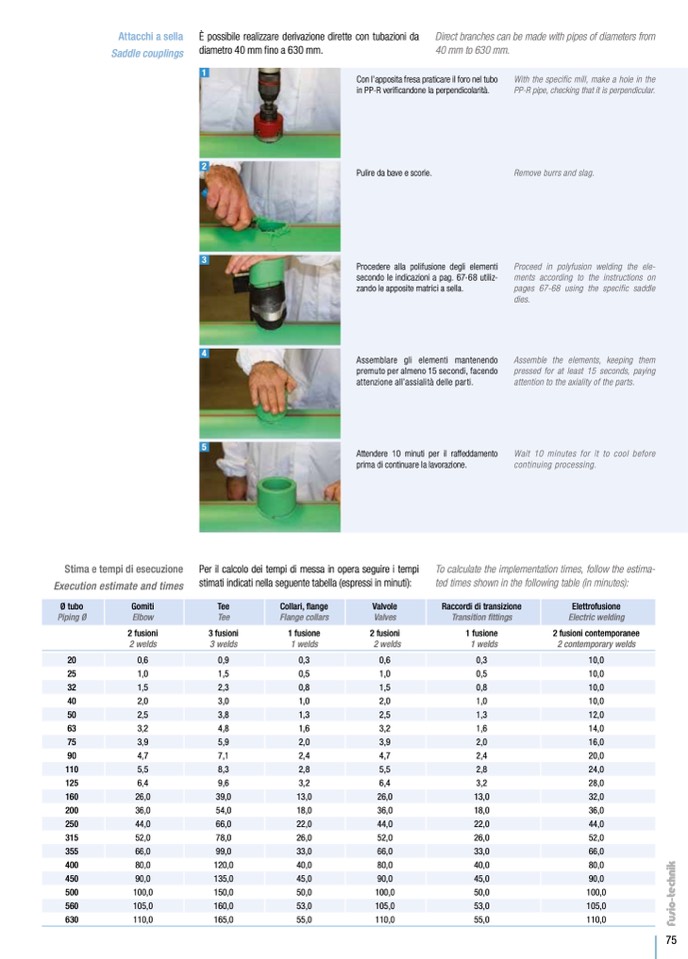

Attacchi a sella

Saddle couplings

È possibile realizzare derivazione dirette con tubazioni da

diametro 40 mm fino a 630 mm.

Direct branches can be made with pipes of diameters from

40 mm to 630 mm.

Stima e tempi di esecuzione

Execution estimate and times

25

40

63

90

125

200

315

400

500

100,0

630

110,0

Per il calcolo dei tempi di messa in opera seguire i tempi

stimati indicati nella seguente tabella (espressi in minuti):

To calculate the implementation times, follow the estima-

ted times shown in the following table (in minutes):

2 fusioni contemporanee

2 contemporary welds

10,0

10,0

14,0

20,0

28,0

36,0

52,0

80,0

100,0

Gomiti

Elbow

2 fusioni

2 welds

0,6

1,0

1,5

2,0

2,5

3,2

3,9

4,7

5,5

6,4

26,0

36,0

44,0

52,0

66,0

80,0

Tee

Tee

3 fusioni

3 welds

0,9

1,5

2,3

3,0

3,8

4,8

5,9

7,1

8,3

9,6

39,0

54,0

66,0

78,0

99,0

120,0

135,0

150,0

160,0

Collari, flange

Flange collars

1 fusione

1 welds

0,3

0,5

0,8

1,0

1,3

1,6

2,0

2,4

2,8

3,2

13,0

18,0

22,0

26,0

33,0

40,0

45,0

50,0

53,0

Valvole

Valves

2 fusioni

2 welds

0,6

1,0

1,5

2,0

2,5

3,2

3,9

4,7

5,5

6,4

26,0

36,0

44,0

52,0

66,0

80,0

90,0

100,0

105,0

Raccordi di transizione

Transition fittings

1 fusione

1 welds

0,3

0,5

0,8

1,0

1,3

1,6

2,0

2,4

2,8

3,2

13,0

18,0

22,0

26,0

33,0

40,0

45,0

50,0

53,0

Elettrofusione

Electric welding

10,0

10,0

12,0

16,0

24,0

32,0

44,0

66,0

90,0

105,0

165,0

55,0

110,0

55,0

110,0

75

1

2

3

4

5

Con l’apposita fresa praticare il foro nel tubo

in PP-R verificandone la perpendicolarità.

Pulire da bave e scorie.

Procedere alla polifusione degli elementi

secondo le indicazioni a pag. 67-68 utiliz-

zando le apposite matrici a sella.

Assemblare gli elementi mantenendo

premuto per almeno 15 secondi, facendo

attenzione all’assialità delle parti.

Attendere 10 minuti per il raffeddamento

prima di continuare la lavorazione.

With the specific mill, make a hole in the

PP-R pipe, checking that it is perpendicular.

Remove burrs and slag.

Proceed in polyfusion welding the ele-

ments according to the instructions on

pages 67-68 using the specific saddle

dies.

Assemble the elements, keeping them

pressed for at least 15 seconds, paying

attention to the axiality of the parts.

Wait 10 minutes for it to cool before

continuing processing.