SPY SERIES - VISUAL DIAGNOSIS MANIFOLD

The new STANDARD!

Why?

The information provided to date by the existing manifold on the market is based on pressures

and temperatures. Important but incomplete information, since the standard sightglass does not

allow us or only partially, to guess the passage of the refrigerant, its phase (liquid or vapour) and

its quality.

How many times, after having a problem on a unit, have we questioned?

... what if I could have observed the presence of water or moisture before?

... what if I could have observed the state of the oil and its mixture with the refrigerant?

... what if I could have seen the presence of contaminants in the refrigerant?

The standard sightglass, incorporated in traditional manifolds, does not help us to obtain useful

indications in this sense, and consequently do not help us in making a more complete diagnosis

about the “health” of the system.

standard sightglass

RECOVER

RECYCLE

REUSE

OPTIMAL

VISIBILITY

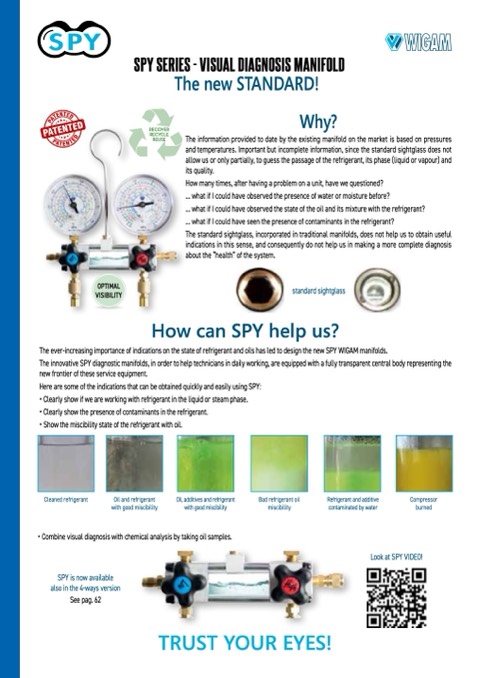

How can SPY help us?

The ever-increasing importance of indications on the state of refrigerant and oils has led to design the new SPY WIGAM manifolds.

The innovative SPY diagnostic manifolds, in order to help technicians in daily working, are equipped with a fully transparent central body representing the

new frontier of these service equipment.

Here are some of the indications that can be obtained quickly and easily using SPY:

• Clearly show if we are working with refrigerant in the liquid or steam phase.

• Clearly show the presence of contaminants in the refrigerant.

• Show the miscibility state of the refrigerant with oil.

Cleaned refrigerant

Oil and refrigerant

Oil, additives and refrigerant

with good miscibility

with good miscibility

• Combine visual diagnosis with chemical analysis by taking oil samples.

SPY is now available

also in the 4-ways version

See pag. 62

Bad refrigerant oil

miscibility

Refrigerant and additive

contaminated by water

Compressor

burned

Look at SPY VIDEO!

TRUST YOUR EYES!