EFFEBI-PRESS

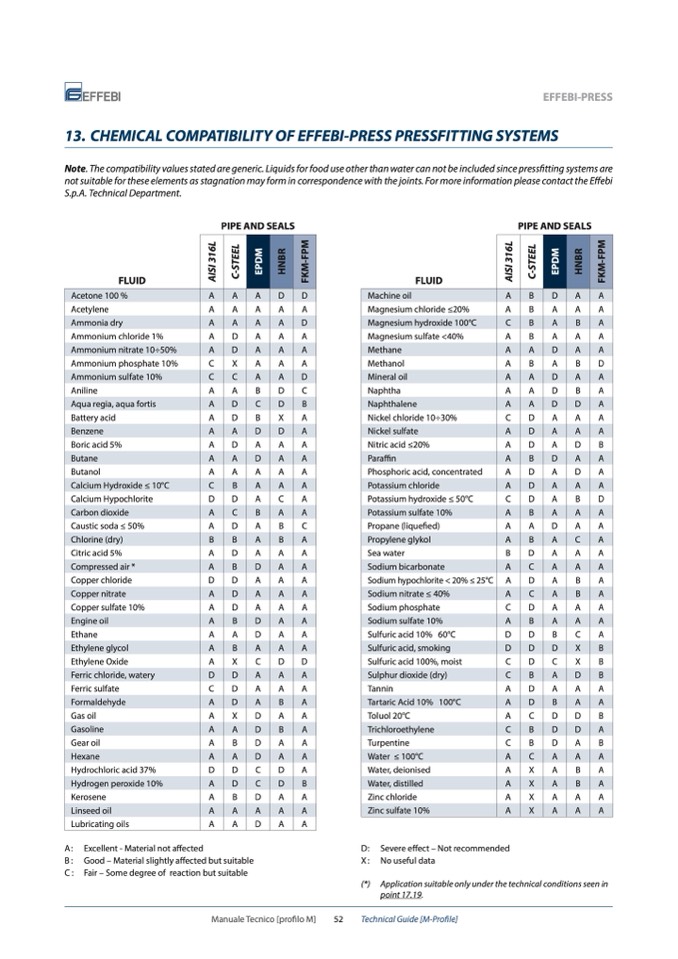

13. CHEMICAL COMPATIBILITY OF EFFEBI-PRESS PRESSFITTING SYSTEMS

Note. The compatibility values stated are generic. Liquids for food use other than water can not be included since pressfitting systems are

not suitable for these elements as stagnation may form in correspondence with the joints. For more information please contact the Effebi

S.p.A. Technical Department.

PIPE AND SEALS

PIPE AND SEALS

Machine oil

Magnesium chloride ≤20%

Magnesium hydroxide 100°C

Magnesium sulfate <40%

Methane

Methanol

Mineral oil

Naphtha

A

A

D

B

A

FLUID

Acetone 100 %

Acetylene

Ammonia dry

Ammonium chloride 1%

Ammonium nitrate 10÷50%

Ammonium phosphate 10%

Ammonium sulfate 10%

Aniline

Aqua regia, aqua fortis

Battery acid

Benzene

Boric acid 5%

FLUID

Butane

Butanol

Calcium Hydroxide ≤ 10°C

Calcium Hypochlorite

Carbon dioxide

Caustic soda ≤ 50%

Chlorine (dry)

Citric acid 5%

Compressed air *

Copper chloride

D

Phosphoric acid, concentrated

Potassium chloride

Potassium hydroxide ≤ 50°C

Potassium sulfate 10%

Propane (liquefied)

Propylene glykol

Sea water

Sodium bicarbonate

Sodium hypochlorite < 20% ≤ 25°C

Sodium nitrate ≤ 40%

Sodium phosphate

Sodium sulfate 10%

Sulfuric acid 10% 60°C

Sulfuric acid, smoking

Sulfuric acid 100%, moist

Sulphur dioxide (dry)

Tannin

A

D

A

A

D

A

C

D

A

A

B

A

A

A

D

A

B

A

B

D

A

A

C

A

A

D

A

A

C

A

C

D

A

A

B

A

D

D

B

D

D

D

C

D

C

C

B

A

A

D

A

A

D

B

A

C

D

C

B

D

C

B

D

A

C

A

A

X

A

A

X

A

A

X

A

A

X

A

D

A

A

A

B

D

A

A

A

A

C

A

A

A

A

A

B

A

B

A

A

A

A

A

C

A

X

B

X

B

D

B

A

A

A

A

D

B

D

A

A

B

A

A

B

A

B

A

A

A

A

A

D

A

A

A

A

D

A

A

A

A

D

A

A

A

A

B

D

A

A

A

A

D

A

A

A

B

A

A

A

A

X

C

D

D

D

D

A

A

A

C

D

A

A

A

A

D

A

B

A

A

X

D

A

A

A

A

D

B

A

A

B

D

A

A

A

A

D

A

A

D

D

C

D

A

A

D

C

D

B

B

D

A

A

A

A

A

A

A

D

A

A

Excellent - Material not affected

Good – Material slightly affected but suitable

Fair – Some degree of reaction but suitable

Copper nitrate

Copper sulfate 10%

Engine oil

Ethane

Ethylene glycol

Ethylene Oxide

Ferric chloride, watery

Ferric sulfate

Formaldehyde

Gas oil

Gasoline

Gear oil

Hexane

Hydrochloric acid 37%

Hydrogen peroxide 10%

Kerosene

A

Linseed oil

A

Lubricating oils

A

Tartaric Acid 10%

Toluol 20°C

Trichloroethylene

Turpentine

Water ≤ 100°C

Water, deionised

Water, distilled

Zinc chloride

Zinc sulfate 10%

100°C

A

A

A

A

A

A

A

A

A

A

D

A

A

D

A

C

X

A

C

C

A

A

A

B

D

C

A

D

C

D

B

A

D

B

X

A

A

A

D

D

A

A

D

A

A

A

A

A

D

A

A

A

A

A

A

A

C

B

A

A

A

D

D

A

C

A

A

C

B

A

A

A

D

A

B

C

B

B

A

B

A

A

D

A

A

A

A

B

D

A

A

D

D

A

A

A

D

A

A

A

A

A

A

A

D

A

B

A

B

C

B

A

B

A

A

A

B

A

A

D

A

A

A

A

A

A

B

A

A

A

A

D

A

A

A

B

D

D

A

A

Naphthalene

Nickel chloride 10÷30%

Nickel sulfate

Nitric acid ≤20%

Paraffin

A

B

D

A

A

A

A

C

D

A

D

A

D

D

D

A

A

A

A

A

A

A

A

D

B

A:

B :

C :

D:

X :

(*)

Severe effect – Not recommended

No useful data

Application suitable only under the technical conditions seen in

point 17.19.

Manuale Tecnico [profilo M]

52

Technical Guide [M-Profile]

A

I

S

I

3

1

6

L

C

-

S

T

E

E

L

E

P

D

M

H

N

B

R

F

K

M

-

F

P

M

A

I

S

I

3

1

6

L

C

-

S

T

E

E

L

E

P

D

M

H

N

B

R

F

K

M

-

F

P

M